DHM® Inspection Solutions

- Stock: Contact us for details

- Click here to: Contact us

- Model: Lyncee Tec DHM Inspection

Incoporate phase imaging into your workflow

DHM® Solutions for Industry

Lyncée Tec's Digital Holographic Microscopy (DHM®) patented technology utilises a video camera to record a hologram produced by the interference between a reference laser beam and the light reflected from a sample.

Lyncée Tec's Digital Holographic Microscopy (DHM®) patented technology utilises a video camera to record a hologram produced by the interference between a reference laser beam and the light reflected from a sample.

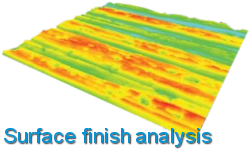

The capture is processed to reconstruct a 3D image that reveals the optical topography information of the sample.

This is all done in real-time without contact and without scanning, making this digital process ideal for high-speed industrial inspection and other, similar applications.

Industrial DHM® Systems

The R100 and R200 DHM® series are compact and lightweight 3D optical profilometers with interferometric resolution. They can be mounted on robot arms and gantry conveyors, and can be easily integrated into multifunctional machines. Existing systems are already in use for display, semiconductor, micro-optics, and other industrial metrologies.

The R100 and R200 DHM® series are compact and lightweight 3D optical profilometers with interferometric resolution. They can be mounted on robot arms and gantry conveyors, and can be easily integrated into multifunctional machines. Existing systems are already in use for display, semiconductor, micro-optics, and other industrial metrologies.

3D information is acquired instantaneously over the full field of view, and at camera frame rate by using a scannerless measurement technology unlike other optical profilometers.

Advantages

- Sample can be measured in transit

- No moving parts ensure robust system with outstanding MTBF

- Environmental vibration effects negated by µs exposure times

- Short acquisition time and high frame rate: Characterise large areas fast for high throughput

These DHM® heads operate in reflection, with either one or two wavelengths (R100 and R200 respectively). They are normally equipped with a single objective, but a fast linear motorised objective changer is an option.

Control is via Lyncée Tec's software suite, however a Software Development Kit (SDK) for integrating into an OEM system is also available.

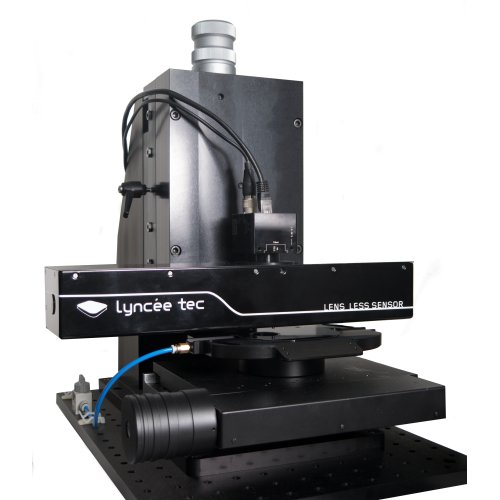

Digital Holographic Macroscope

Specifications

- 32 mm2 field of view

- 35 µm lateral resolution

- 0.5 nm vertical resolution

- 30 mm working distance

- 0.15° acceptance angle

The first macroscopic configuration of Lyncée Tec's Reflection DHM® enables measurement of 3D topography with a large field of view. As with other DHM® products, the macro-sensor is one or two laser non-scanning instrument capturing data at unrivaled acquisition speeds.

The recently patented technology opens up new applications where a sub-nanometric vertical resolution is required within an extended field of view compare to standard microscope configuration.

The macro-sensor has been developed for automated measurement, so all the critical components are easily accessible. In a stand-alone configuration it is equipped with a motorised stage. A 'head only' configuration is available for integration onto larger equipment.

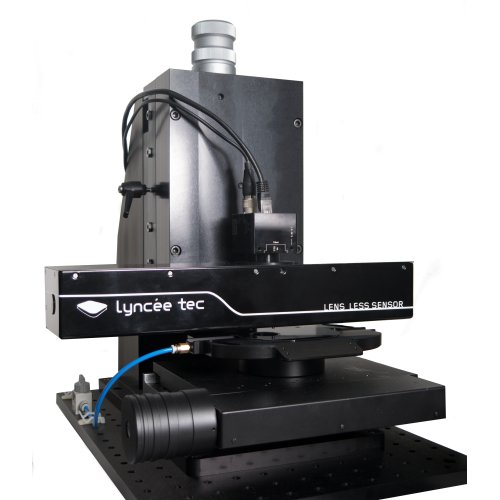

'Lens Less' Sensor

The 'Lens Less' Sensor is a fixed field of view DHM® from Lyncée Tec for measuring 3D topography with sub-nanometric resolution. The digital holography technology offers significant advantages when compared to other 3D optical profilometer systems.

Features

Features

- Fast measurement

- Insensitive to surrounding vibrations

- Digital focussing

- Single or dual wavelength configuration

- Compact design for easy integration

- Ideal for automation

- Camera outside of the main body for easy maintenance

- External laser source for easy integration and maintenance

- Adapted to your needs

- Choice of laser sources

- Higher resolution sensor option

The unique patented design of the Lyncée Tec robust Lens Less Sensor makes it ideal for industrial applications.

| File Name | Size | Link |

|---|---|---|

|

|

207.42KiB | Download |